At Ladata, we believe successful plastic part production begins long before the mould is cut — it starts with understanding how molten material will behave within your mould.

Our Mould Flow Simulation Assistance service combines advanced software tools with hands-on engineering expertise to de-risk tooling investment, improve part quality, and accelerate production readiness.

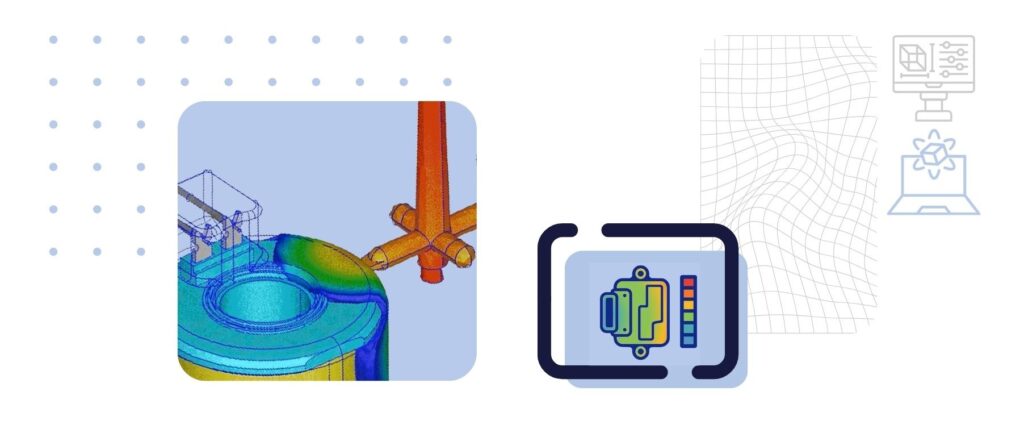

Mould flow simulation reveals critical issues that are otherwise hidden in CAD. At Ladata, our simulation engineers act as an extension of your design team, running virtual injection moulding trials that evaluate:

Filling behaviour

Potential presence of sink marks and dents

Weld line formation

Air trap locations

Cooling efficiency

Packing pressure

Warpage predictions

Premould behaviour

Other

Whether you’re building a single-shot part, an insert-moulded connector, or a bi-material overmoulding assembly, these insights guide smarter gate placement, part geometry, and tooling strategies.

As the UK-based engineering arm of Layana (Taiwan), Ladata brings decades of experience in injection moulding, in-mould assembly, and high-specification tooling. We help validate your designs under real-world constraints — material behaviour, wall thickness variation, thermal gradients, and cycle time — all long before production begins.

We simulate single- and multi-shot parts, including pre-mould and overmould combinations, to evaluate and optimize every aspect of the injection process. Our mould flow analysis includes gate placement, flow length, pressure drop, weld line prediction and control, runner system configuration (hot or cold), air trap detection, venting recommendations, cooling time estimation, shrinkage prediction, as well as the potential presence of sink marks and detents. Based on these results, Ladata provides design change suggestions and manufacturability guindance.

Our engineers refine and optimize CAD geometry to ensure it’s simulation-ready and tooling-compatible from the start. This includes cleaning up the model, preventing mesh errors, defining optimal draft angles, and recommending gate locations, gate count, and the most suitable runner system (cold or hot). We also adjust wall thicknesses to improve material flow, cooling efficiency, and demoulding performance—laying the foundation for a seamless transition from design to manufacturing.

Whether you’ve already selected a specific plastic material or need Ladata to recommend suitable alternatives based on performance, cost, and processability, we simulate using verified manufacturer data for shrinkage, viscosity, and cooling rates to ensure accurate, material-specific results. Supported materials include PP, HIPS, AS, BBS, PMMA, POM, PC, PA (including PA6, PA46, and PA+GF), PBT, PET, PPS, PU, PC+ABS, and other engineering or high-performance polymers commonly used in automotive, electronics, appliances, and industrial applications.

*With in-house knowledge in toolmaking, automation, and quality, we don’t stop at simulation. We turn results into actionable recommendations for gating, ejection, cavity balancing, and even automation setup.

Holistic Approach: Design + Simulation + Tooling + Production

We don’t simulate in isolation. Ladata bridges the gap between your design intent and actual manufacturing behaviour. Our parent company, Layana, runs full-service operations with progressive dies, multi-cavity moulds, and high-volume production — giving our simulation work real-world grounding.

Precision Matters: ±0.01 mm Across Insert & Overmoulded Parts

Simulations are aligned with our micro-tolerance capabilities, validating shrinkage compensation, dimension control, and critical feature formation across complex geometries.

Tooling Investment Risk Mitigation

Our flow reports highlight potential tooling issues before steel is cut — avoiding costly rework and delays. We also recommend optimal parting lines, slider/ejector placement, and gating schemes.

Multi-Industry Experience

From medical equipment parts to automotive EV connectors, Ladata supports high-performance parts across sectors that demand zero-defect quality and repeatability.

Your questions answered

Mould flow simulation is a virtual testing method that shows how molten plastic flows inside a mould. It predicts issues like air traps, weld lines, short shots, or excessive pressure — helping engineers fix potential problems before making the tool. This saves time, reduces tooling iterations, and improves part quality from the first shot.

As early as possible — ideally when your part design is nearing completion but before tooling design and development starts. Early simulations allow for part geometry refinements, better gate placement, and tooling cost optimization. Late-stage changes are harder and more expensive to implement.

Any part can benefit, but simulations are especially critical for:

Yes. We typically require 3D CAD files (STEP preferred) and your chosen plastic material. If no material is selected, we can assist in choosing one and simulate with material dataset values.

FROM DESIGN TO TOOLING — WE MAKE MOULDS SMARTER

Let’s collaborate early to optimize your design, reduce costs, and launch with confidence.