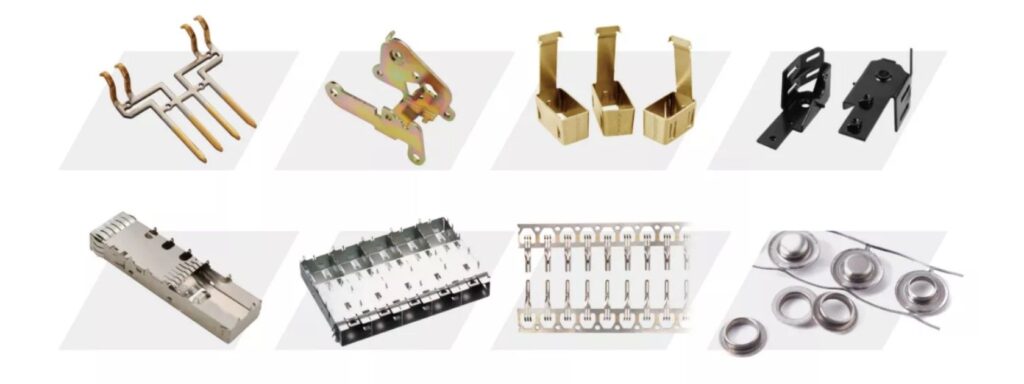

Metal stamping is at the core of our manufacturing capabilities. This process involves feeding metal sheet or coil into a press machine, which uses custom-designed dies and high force to punch and form the metal into precise shapes. The result is the rapid production of complex metal parts with excellent repeatability and accuracy. At Layana, we specialise in custom metal stamping solutions tailored to your product requirements – whether you need tiny micro-precision connectors or robust deep-drawn components.

We have 40+ years of know-how in tool and die making, which means every stamping die is expertly engineered in-house for optimal performance. Our seasoned team of toolmakers (some with four decades of experience) ensures that even the most intricate designs can be manufactured efficiently and within tight tolerances. All tooling design, assembly, and maintenance are done internally, guaranteeing quality control over the entire stamping process.

At Ladata, tooling fabrication is the foundation of precision in custom metal stamping. The process starts with evaluating part geometry and blank size, followed by layout design and the drafting of components and die plates. Using advanced CAD/CAM software, our engineers create tooling designs that account for tolerances, material behaviour, and forming complexity. Once finalized, components are manufactured in-house using high-precision processes such as grinding, EDM, drilling, milling, and heat treatment. This ensures high durability, dimensional accuracy, and smooth operation. We build progressive, transfer, simple, and compound dies tailored to each project’s needs.

Once the die is ready, we move to metal stamping. Coil or sheet metal is fed into high-speed stamping presses, where it’s shaped in multiple stages. Key operations include piercing (to create holes or alignment features), guiding (for precise material positioning), trimming and forming (bending, chamfering, radiusing, etc.), and drawing and deep drawing (for parts with significant depth). A final blanking or cut-off step separates the finished part from the strip.

Every tool goes through a tryout and validation phase before mass production. Sample parts are tested for dimensional accuracy, forming quality, and surface finish. Our toolmakers fine-tune the die until it meets all specifications. This tooling and stamping process is part of Ladata’s larger Product Development Process, which begins with RFQ evaluation and R&D and continues through tooling, trial runs, validation, and production. With all capabilities — design, tooling, stamping, and quality control — under one roof, we ensure faster lead times, better communication, and full control over part quality.

what makes us different

Full In-House Tooling Expertise We design, manufacture, and assemble all stamping dies in-house — including progressive, transfer, and compound dies. Some of our toolmakers have over 40 years of experience.

Our stamping presses range from 25T to 300T, handling material thicknesses from 0.02 mm to 8 mm with tolerances as tight as ±0.01 mm. Tool sizes can go up to 2,500 x 1,000 x 550 mm.

To boost efficiency and scalability, we offer in-house automation solutions for post-stamping processes, sub-assemblies, and final assembly lines — tailored to your production needs.

All stamped parts are traceable through our ERP-integrated quality system, supported by inspection reports, PPAP documentation, and optional real-time sensor feedback in critical applications.

Layana/Ladata unites metal stamping, plastic injection moulding, insert moulding, overmolding, and in-mould assembly under one roof. This vertical integration not only enables advanced bi-material solutions, but also eliminates the need for inter-supplier transfers — reducing logistics complexity, lead times, and handling risks.

Ladata/Layana ensures dimensional accuracy and consistency with state-of-the-art inspection tools — including ZEISS CMM Contura RDS, automated optical inspection systems, and a ATMOS 3D scanner integrated with robotics, guaranteeing traceability, precision, and full confidence.

Ladata's metal drawing capabilities enable the production of deep, hollow, and complex-shaped metal components with high precision and efficiency. With decades of expertise and servo presses up to 300 tons, Ladata handles diameters from 1.5 to 100 mm, material thickness up to 2.5 mm, and roundness tolerances as tight as 0.05 mm.

Ladata’s fine blanking capabilities offer high-precision cutting solutions ideal for applications requiring smooth, burr-free edges and tight tolerances (up to ±0.01 mm). With in-house tooling expertise, presses ranging from 25T to 300T, and the ability to process materials from 0.02 mm to 8 mm thick, Ladata delivers cost-effective fine blanking for complex shapes without secondary operations.

Ladata’s micro stamping capabilities deliver ultra-precise miniature metal components under 10 mm with tolerances as tight as ±0.01 mm, ideal for electronics, medical, and automotive applications. With in-house tooling, simulation, and decades of experience, Layana handles complex micro features including bending, deep drawing, coining, and chamfering across materials like copper, stainless steel, and titanium.

Your questions answered

Ladata offers a full range of custom metal stamping solutions, including single-hit stamping, compound dies, progressive die stamping, and transfer die stamping. Whether you need ultra-precise micro parts, fine blanking stamped parts or deep-drawn structural components, we tailor the tooling and process to your specific product requirements.

Ladata offers a fully integrated manufacturing environment that goes far beyond standard stamping services. We design, build, and maintain all tooling in-house, supported by toolmakers with over 40 years of experience. Our dedicated automation engineering team enables scalable solutions with integrated post-processing, sub-assembly, and final assembly lines. We operate under a Total Quality Management system and are certified to the IATF 16949 standard, ensuring full traceability and process control for demanding industries such as automotive, medical, and electronics. Additionally, our in-house plastic injection moulding department allows us to offer advanced insert moulding and overmolding solutions — all under one roof for unmatched efficiency and supply chain simplification.

We provide complete in-house capabilities for tooling and custom metal stamping to ensure precision, efficiency, and consistent quality. Our team designs, builds, and maintains complex multi-station dies, with support for tooling sizes up to 2,500 × 1,000 × 550 mm. Our stamping presses range from 25 to 300 tonnes, processing materials from 0.02 mm to 8 mm thick, with tolerances as tight as ±0.01 mm.

We offer total quality management (TQM) including high-precision CMM, automated optical systems, and integrated quality tracking. For high-demand applications, we meet stringent quality requirements and ensure full compliance with industry standards such as IATF 16949.

Ladata has a dedicated automation engineering team to support post-stamping processes, sub-assemblies, and final assembly. This enables seamless integration into your production line and supports high-volume scalability while reducing lead times.

Yes, we offer total engineering solutions that include a wide range of surface finishing treatments. These services cover electroplating, heat treatment, deburring, passivation, and other processes. This integrated approach allows us to deliver finished parts that meet both functional and cosmetic requirements — all within a streamlined and quality-controlled supply chain.

Yes, we offer total engineering solutions that include a wide range of surface finishing treatments. These services cover electroplating, heat treatment, deburring, passivation, and other processes. This integrated approach allows us to deliver finished parts that meet both functional and cosmetic requirements — all within a streamlined and quality-controlled supply chain.

From Design to Production — We’ve Got You Covered

Let’s connect and explore the possibilities.